Standard Equipment on ALL VICTORY machines includes plasma cutting components that some manufacturers call options. Automatic Torch Height Control, Arc Voltage Readouts, Magnetic Torch Collision, Breakaway with Movement Stop Action, Laser Pointer, Easy Restart, Dual Side Servo Drives, Pneumatic Pre-tensioning, Direct Coupled Planetary Nidec Gear Boxes (5year Warranty), Sealed Roller Bearings on Y-Axis, Dual Linear Ways on X-Axis, IGUS Full Cable Carrier, IGUS Chain Flex Shielded Cables, Extensive Grounding, Hypertherm EDGE Connect Controller, Touch Screens, Freight, Installation, Onsite Operator Training.

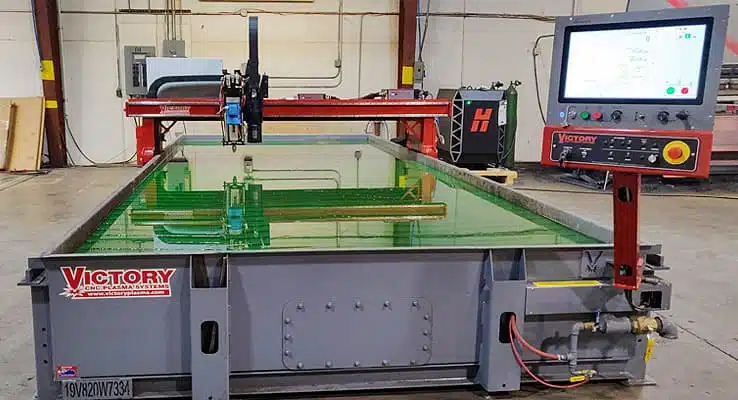

Victory TS

The Victory TS is a light industrial version of our unitized industrial CNC systems. The TS is an excellent fit for trade schools or those looking to purchase a lighter-duty plasma-cutting system. The Victory TS is a turnkey system that features a fully welded water or downdraft table supporting full sheets of 1” plate, adjustable water levels, an all-steel gantry, and dual side servo drive weighing about 3,800 lbs. This system includes the Victory TS controller powered by Hypertherm’s Phoenix operating software and your choice of any Hypertherm Powermax plasma. Available configurations include 5’ x 10’ or 6’ x 10’ with a downdraft or water cutting bed. Systems start at $56,800 and include the Powermax. Options include ox-fuel torch and ProNest LT. Visit the Victory TS system page.

Victory Pro

•The Victory Pro is a medium-duty version of our unitized industrial CNC systems engineered just for the MAXPRO. The PRO is an excellent fit for those looking for a midweight, 100% duty cycle, dual gas, liquid-cooled, plasma cutting system. This turn-key system can feature a welded water table or down draft table that supports full sheets of 2” plate. The water table has fully adjustable water levels. Both tables have an all-steel gantry with dual-side Yaskawa servo drives. Equipped with the Hypertherm EDGE Connect TC controller. Weighing about 4,800 lbs, this machine supports MAXPRO production perfectly. Available in 5’x10’ or 6’x12’ cutting beds. Systems starts at $80,300, Options include: Ox-Fuel Torch and Pronest LT. Visit the Victory Pro system page.

Victory Unitized

The Victory Unitized CNC plasma system is an excellent choice for those looking to purchase a turnkey industrial plasma system. This dual-side drive system features a W4-13 beam welded frame with a 3/16” plate downdraft or water-cutting bed supporting full sheets of 3” plate, all welded overrun steel gantry. Top-of-the-line Yaskawa servo motors, Nidec gearboxes, and helical gear rack. Unitized machines are manufactured in sizes from 5’ x 10’ through 8’ x 20’. This system features the EDGE Connect TC controller and your choice of any of the fine Hypertherm new technology X-Definition True Hole, liquid-cooled plasma power supplies, XPR170, XPR300, and the new XPR460 with Autogas and Plasma Marking without changing consumables. Not only a great machine for mild steel, this is the machine you want for stainless and aluminum cutting. Systems start at $168,600 with plasma. Installation and onsite operator training is included. Options to tailor your system include gantry extension for off-table cutting, ProNest, 3/4hp Drill, Ox-fuel torch, and SnapLoc straight-line bevel torch mount. Visit the Victory Unitized system page.

Victory Rail & Gantry

The Victory Rail & Gantry CNC plasma system features floor-mounted, knee-high rails, dual-side drive steel open-end gantry system that rides over a downdraft or water cutting bed supporting full sheets of 3.5” plate ranging from 5’ x 10’ to 10’ x 30’. This dual-side drive top-of-the-line Yaskawa servo motors and Nidec gearboxes system features all Hypertherm components, including the EDGE Connect TC controller and your choice of X-Definition, True Hole XPR170, XPR300, XPR460 plasmas with VWI Autogas and Plasma Marking. These machines are available without the cutting table for installation over existing cutting tables or buyer-built cutting tables. Victory will supply factory drawings for buyer-built worktables, or the buyer may design a worktable. Options include a 3/4hp CNC Drill, Multiple Oxy-fuel torches, Multiple Plasma Cutters, a 12” diameter Outboard Tube Cutter and SnapLoc straight-line bevel Torch Mount, Off Table Cutting. Systems start at $181,200, including installation and onsite operator training. Visit the Victory Rail & Gantry system page.

Victory Bridge

The Victory Bridge CNC plasma system features a floor-mounted dual-side drive welded bridge system that rides over a downdraft or water-cutting bed supporting full sheets of 4” plate, ranging from 5’ x 10’ to 20’ x 100’. These machines are available without the cutting table for installation over existing cutting tables or buyer-built cutting tables. Victory will supply factory drawings for buyer-built worktables, or the buyer may design a worktable. Our turnkey system features all Hypertherm plasma components, including the bridge-mounted EDGE Connect TC controller, unmatched X-Definition XPR170, XPR300, XPR460 plasma cutters, VWI Autogas, True Hole, and Plasma Marking. Options include a 3/4hp or 3hp CNC drill, Multiple oxy-fuel torches, Multiple plasma cutters, a 14” diameter Outboard Tube Cutter, and a 5-axis Full Contour Beveling. Systems start at $189,700 and include installation and onsite operator training. Visit the Victory Bridge system page.

System Options

To meet virtually every need, Victory plasma cutting systems feature options such as AutoGas, integrated pipe cutter, manual bevel, oxy-fuel cutting, and drilling.

Custom Plasma Cutting Systems

Victory builds everything in-house, and we have the engineering and fabricating expertise to accommodate your special projects and needs.

You must be logged in to post a comment.